¿Tu empresa enfrenta estos desafíos?

Pérdidas económicas

Dificultad para identificar comportamientos fuera de rango que resultan en robos y pérdidas de dinero.

Falta de visibilidad

Dificultad para monitorear actividades y localizar camiones y remolques.

Congestión en los accesos

Verificaciones manuales que generan demoras importantes

Procesos manuales

Información tardía y errores que dificultan decisiones rápidas

Documentación complicada:

Dificultad para cumplir con certificaciones y auditorías

Integración de sistemas

Necesidad de centralizar información en sistemas existentes

Conoce tu siguiente Ventaja Competitiva

- Sustituye tareas manuales automatizando punto a punto los accesos y patios de maniobra de tu compañía.

- El uso de una tecnología muy poderosa y capaz de obtener datos analíticos de tu operación en tiempo real.

Nuestras soluciones

Yard Management System

- Automatización inteligente: Uso de visión computacional para captura de matrículas vehículares y números de contenedores de carga.

- Visibilidad 360° en tiempo real: Monitoreo completo de todas las unidades en patio, tiempos de carga y cuellos de botella.

- Integración perfecta: Conecta fácilmente con tus sistemas ERP, TMS y WMS para un flujo de datos eficiente y centralizado.

- Seguridad optimizada: Detección de anomalías y alertas automáticas para prevenir robos y pérdidas.

- Cumplimiento normativo: Captura fotográfica automática y documentación digital para cumplir con certificaciones y auditorías.

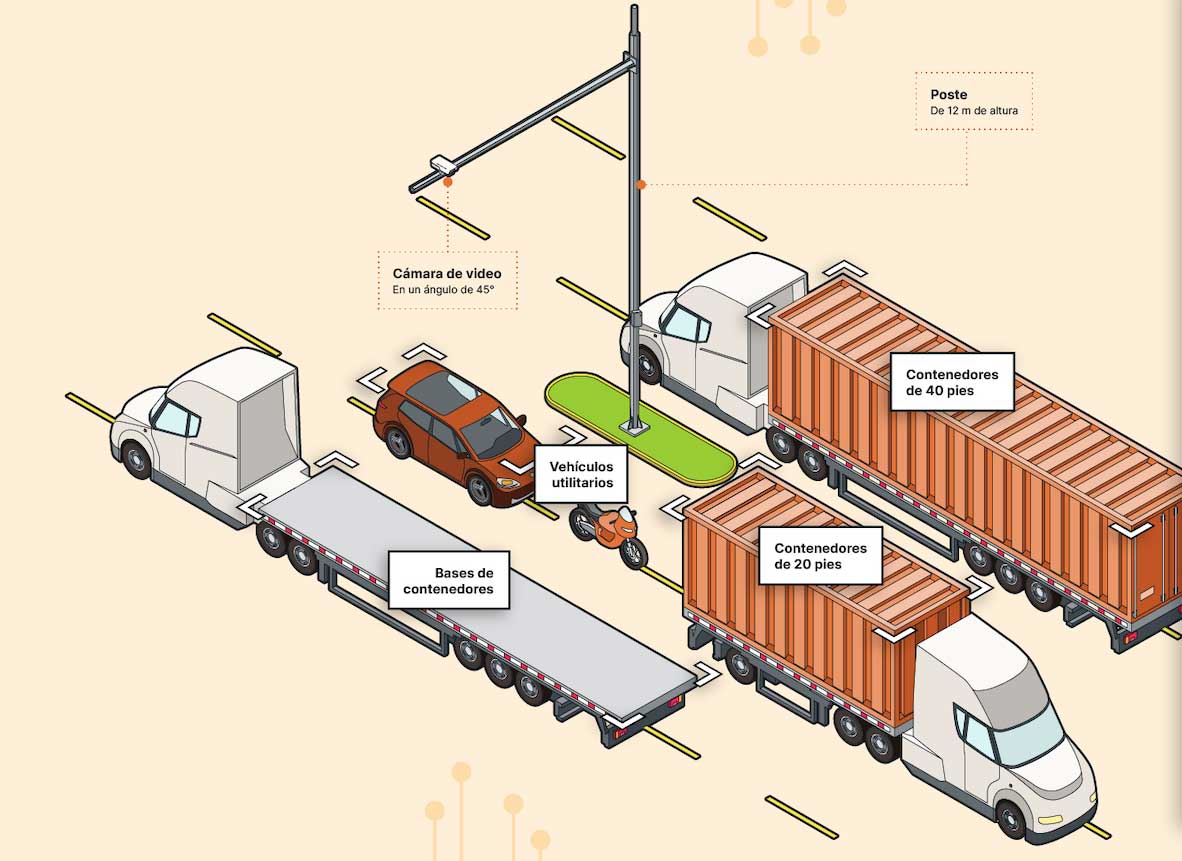

Gestión de contenedores

- Solución diseñada para controlar el flujo de contenedores en patios de maniobra y sistemas ferroviarios. Usando cámaras de video obtenemos la siguiente analítica: Número de contenedores que ingresan o salen de un patio, dimensiones del contenedor (40ft o 20ft). Adicional identificamos plataformas vacías y vehículos utilitarios.

- Capacidad para leer del código ISO 6346 en alguno de los costados del contenedor, ya sea sobre una plataforma terrestre o de tren, parada o en movimiento.

- Ideal para cualquier patio de maniobras sin grandes inversiones en infraestructura.

- Aplicaciones para control de acceso, patios de maniobra, aduanas y seguros.

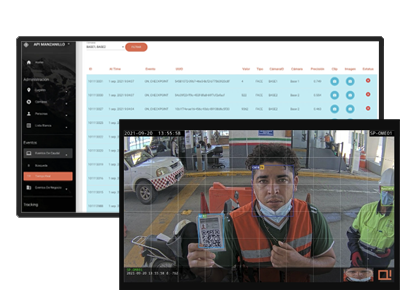

Control de acceso inteligente

Nuestra tecnología de control de acceso biométrico facial y lectura de placas, es ideal para aquellas empresas que buscan un sistema con capacidades de personalización e integración que les permita alcanzar funcionalidades que satisfagan las necesidades reales de su negocio, sin la limitante que los productos genéricos tienen.

- Acceso a través de lectura de rostro, código QR o ambos de forma ágil y segura. Enrolamiento con una foto.

- Control de acceso vehicular a través de la lectura automática de placas.

- Soporta integración con periféricos como torniquetes o barreras, bases de datos, ERP´s, VMS, sistemas legados.

¿Qué esperar cuando implementas tu proyecto con Quantum Labs.

01

02

03